China OEM Embedded Fixing Magnets - High definition China Neodymium Magnetic Nailing Plate Magnetic Fixing Plate Solid Steel Precast Concrete Magnet Shuttering Magnets – Saixin

China OEM Embedded Fixing Magnets - High definition China Neodymium Magnetic Nailing Plate Magnetic Fixing Plate Solid Steel Precast Concrete Magnet Shuttering Magnets – Saixin Detail:

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for High definition China Neodymium Magnetic Nailing Plate Magnetic Fixing Plate Solid Steel Precast Concrete Magnet Shuttering Magnets, In case you pursuit the Hi-quality, Hi-stable, Aggressive price elements, corporation name is your greatest choice!

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for China Shuttering Magnets, Precast Magnet, With a wide range, good quality, reasonable prices and stylish designs, our items are extensively used in public placesand other industries. Our goods are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Product Description

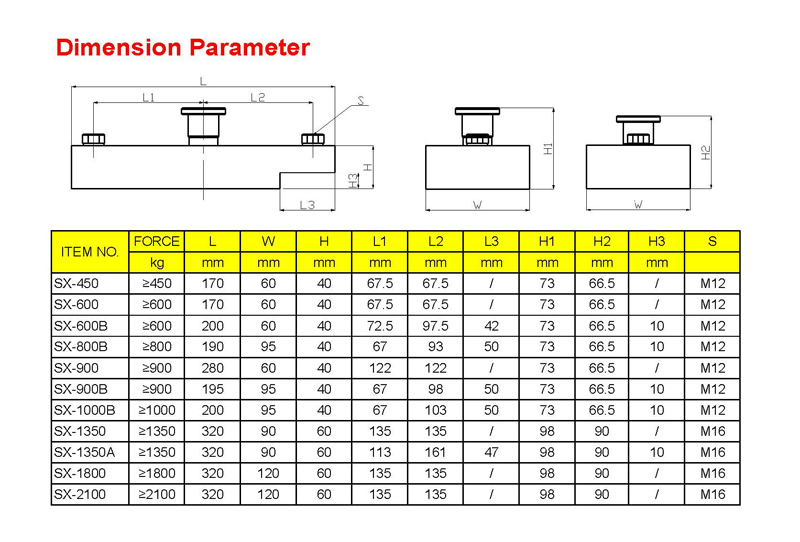

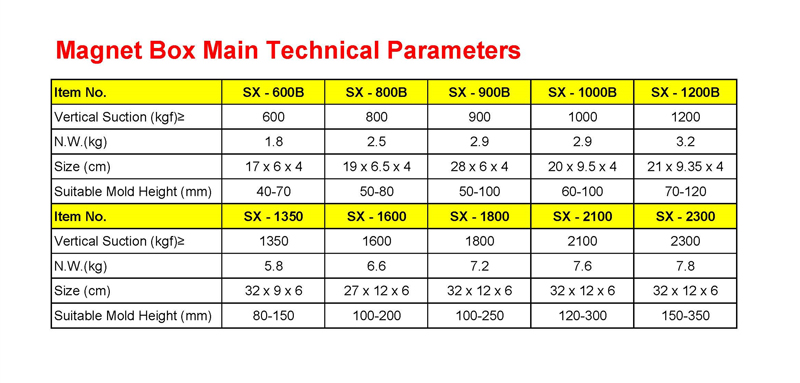

Precast concrete magnet is a new magnetic assembly which is used to fix the formwork in precast industry. The assembly consists of some strong neodymium magnets and steel plates which form to certain designed magnetic circuit. This magnetic circuit provides very much strong adhesive force to any ferrous workpiece. We develop the push ON/OFF button to open or close the magnetic power outside of the box.

SAIXIN® SX-2100 magnet box Vertical pulled off force ≥2100 kgs,external dimension 32X12X6CM,N.W.7.6KGS,suitable for produce the thickness more than 150 mm solid wall plate .

KEY BENEFITS OF SHUTTERING MAGNETS:

1. Reducing the complexity and time of the installation of formwork (up to 70%).

2. Universal use for mass production of concrete products, and piece products of all forms on the same steel table.

3. Eliminates the need for welding, shuttering magnets does not damage the steel table.

4. Makes it possible to produce different shape and size concrete elements.

5.The main advantage of the shuttering magnets is that you do not need to have a lot of different forms for different products, you need to have a set of magnets, adapters for different height boards and steel table.

Instruction

There is an ON/OFF button on the top of the shuttering magnets. At work state, press the button, magnet box fixed the shuttering on the platform firmly, Pull up the button with lever, magnet box is at closed state and can be moved.

(1) The suction of magnet box is based on thickness and smooth degree of the platform, the thicker and smoother the better. And lateral shear force depends on the suction of magnet box and the friction coefficient of the touching surface.

(2)Two screws on two sides of the magnet box can be connected with different adapter, fix different formworks, such as steel angle, steel channel, etc.

(3)SAIXIN® magnet box is made of permanent neodymium magnets, In theory, if the MAX working temperature is below 80℃ and the magnet is not damaged or corroded, the suction will be lasted forever.

Maintenance And Safety Guidelines

(1)In order to avoid the magnet box damaging, do not crash and use hard tools to knock it. Please knock with rubber hammer if must use tools.

(2) Magnet box touching surface should be kept clean and smooth, avoid the scrap iron or concrete grout going inside the box, otherwise the button flexible degree will be affected and the magnet will be slanted, caused the magnet can not be fixed on the platform closely and the suction weakened.

(3)As suction of magnet box is very strong, please avoid closing it to precision instruments,electronic instruments and other iron material. Once they absorb together, it is difficult to separate. Suggest making special tool box to keep them.

(4)Magnet box touching surface should be kept clean and smooth always. And it should be oiled when storage. Max working and storage temperature should be below 80℃,and no corrosive medium around. Always check if the working surface fix the platform closely and the button flexible degree to ensure the normal use.

(5) After using , clean the magnet boxes, and put on stainless steel tool holder. Do not use iron tool holder.

Product detail pictures:

Related Product Guide:

Adhering for the theory of "quality, services, performance and growth", we have received trusts and praises from domestic and worldwide shopper for China OEM Embedded Fixing Magnets - High definition China Neodymium Magnetic Nailing Plate Magnetic Fixing Plate Solid Steel Precast Concrete Magnet Shuttering Magnets – Saixin , The product will supply to all over the world, such as: Jordan , Manchester , Nepal , We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!