Low price for Precast Shutter Magnetic - Shuttering Magnet, Precast Concrete Magnet, Magnetic Shuttering clamp for Prefabricated Buildings, Magnetic System for Formwork – Saixin

Low price for Precast Shutter Magnetic - Shuttering Magnet, Precast Concrete Magnet, Magnetic Shuttering clamp for Prefabricated Buildings, Magnetic System for Formwork – Saixin Detail:

Product Description

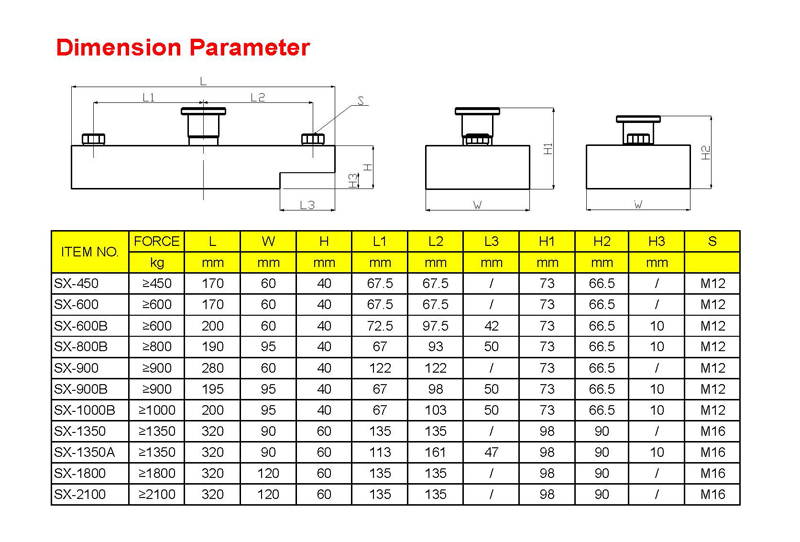

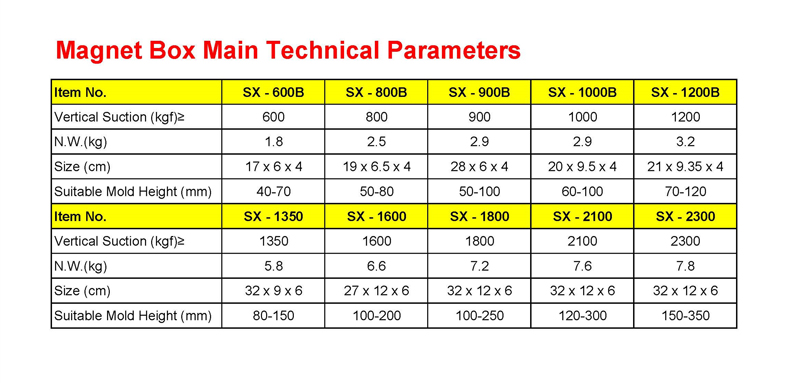

1350KG Construction Shuttering Magnet, Precast Concrete Shuttering Magnet Box, Magnetic Shutter Box for Prefabricated Buildings, Shuttering Magnet for Formwork System Precast China.

KEY BENEFITS OF SHUTTERING MAGNETS:

1. Reducing the complexity and time of the installation of formwork (up to 70%).

2. Universal use for mass production of concrete products, and piece products of all forms on the same steel table.

3. Eliminates the need for welding, shuttering magnets does not damage the steel table.

4. Makes it possible to produce radial products.

5. A small cost of a set of magnets. The average payback of about 3 months.

6. The main advantage of the shuttering magnets is that you do not need to have a lot of different forms for different products, you need to have a set of magnets, adapters for different height boards and steel table.

Instruction

There is an ON/OFF button on the top of the shuttering magnets. At work state, press the button, magnet box fixed the shuttering on the platform firmly, Pull up the button with lever, magnet box is at closed state and can be moved.

(1) The suction of magnet box is based on thickness and smooth degree of the platform, the thicker and smoother the better. And lateral shear force depends on the suction of magnet box and the friction coefficient of the touching surface.

(2)Two screws on two sides of the magnet box can be connected with different adapter, fix different formworks, such as steel angle, steel channel, etc.

(3)SAIXIN® magnet box is made of permanent neodymium magnets, In theory, if the MAX working temperature is below 80℃ and the magnet is not damaged or corroded, the suction will be lasted forever.

Maintenance And Safety Guidelines

(1)In order to avoid the magnet box damaging, do not crash and use hard tools to knock it. Please knock with rubber hammer if must use tools.

(2) Magnet box touching surface should be kept clean and smooth, avoid the scrap iron or concrete grout going inside the box, otherwise the button flexible degree will be affected and the magnet will be slanted, caused the magnet can not be fixed on the platform closely and the suction weakened.

(3)As suction of magnet box is very strong, please avoid closing it to precision instruments,electronic instruments and other iron material. Once they absorb together, it is difficult to separate. Suggest making special tool box to keep them.

(4)Magnet box touching surface should be kept clean and smooth always. And it should be oiled when storage. Max working and storage temperature should be below 80℃,and no corrosive medium around. Always check if the working surface fix the platform closely and the button flexible degree to ensure the normal use.

(5)After using , clean the magnet boxes, and put on stainless steel tool holder. Do not use iron tool holder.

Product detail pictures:

Related Product Guide:

We are going to dedicate ourselves to providing our esteemed buyers together with the most enthusiastically thoughtful products and services for Low price for Precast Shutter Magnetic - Shuttering Magnet, Precast Concrete Magnet, Magnetic Shuttering clamp for Prefabricated Buildings, Magnetic System for Formwork – Saixin , The product will supply to all over the world, such as: United Arab Emirates , Lithuania , belarus , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

We have been looking for a professional and responsible supplier, and now we find it.