Magnetic Shuttering System Precast Concrete Form For Floor Panel

MAGNETIC SHUTTERING SERIES

SAIXIN shuttering systems have good outstanding qualities under tough practical testing. Our magnetic shuttering systems can be used flexibly, rapidly, safely and efficiently in every field.

with the development of technology in precast concrete industry, more and more buildings are used precast concrete products, so that magnetic shuttering system more popular over the years.

Magnetic shuttering system is called magnetic formwork, and placed on steel pallet according to your demand. Maybe you will feel it is very simple the first time you see, but quality warranty of our products 3 years at least, it is difficult for us, including construction and metal quality etc, only through integrating all the conditions that will produce the high quality products.

Key Features:

1. high-performance magnets, strong force secure the shuttering against sliding.

2. easy positioning, fixing and removal of the shuttering, either in manual, crane or robotic handling.

3. provide a cost effective, efficient solutions for the production of high quality precast concrete elements.

4. special tailor-made shape, height & length, on the basis of your individual requirements.

We also can produce shuttering as per your design.

We provide customized services, special tailor-made shape, height & length are on the basis of your individual requirements.

Please do not hesitate to contact with us.

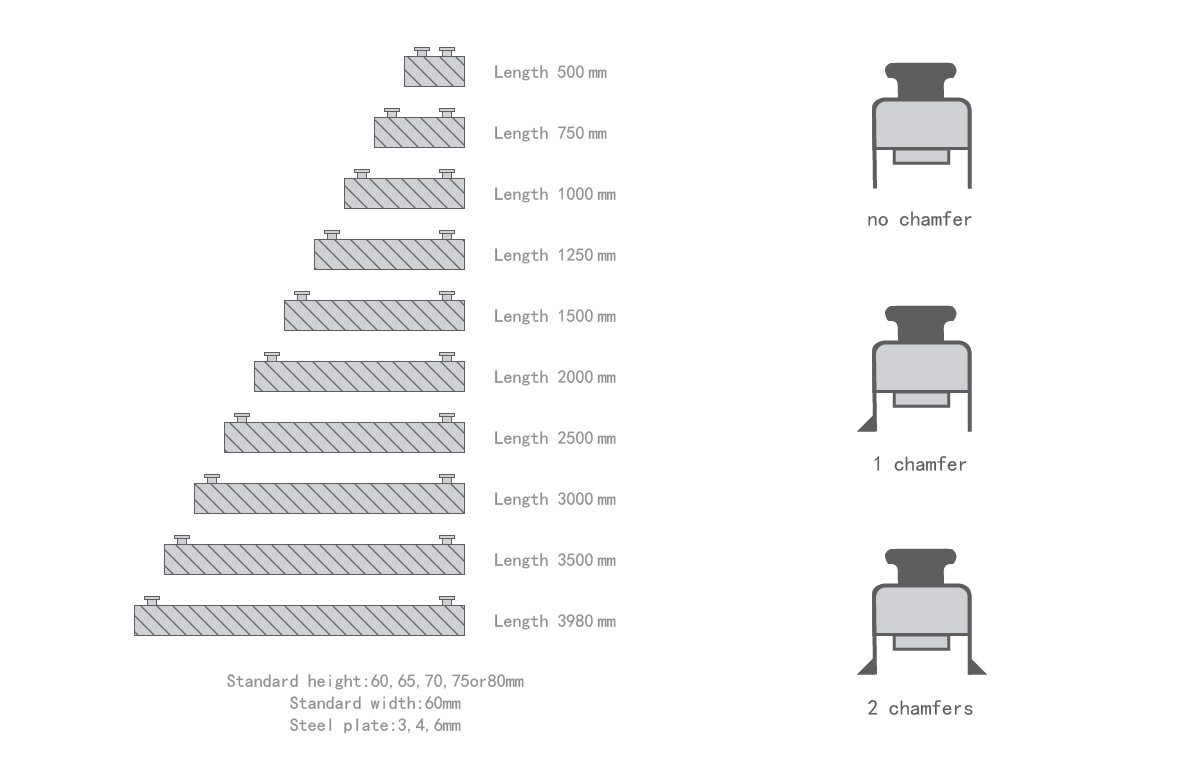

SHUTTERING SYSTEM DESCRIPTION

·Integrated high-performance magnet

·Shuttering length: 320 mm up to 3980 mm

·Basic width: 50 mm up to 200 mm

·Completely adjustable to several heights: 40 mm up to 500 mm

·Sharp edged or chamfered

·Easy positioning

·Easy loosening and fixing of the shuttering

·Less set up time

·Easy crane handling

·Fixation of inserts at the wood shuttering is possible

·Useable for SCC and normal concrete

SHUTTERING TECHNOLOGICAL PROCESS

Steel plate steel section

flattening ↓ ↓ straightening

Cutting cutting

↓ ↘ ↙

Bending drilling

↘ ↓

welding

↓

straightening

↓

Polishing → milling

↓ ↙

inspection

↓ pass

painting

↓

Assembling with magnet system

Application