With the vigorous development of domestic prefabricated buildings, more and more PC component manufacturers begin to use magnetic fixation, but the quality of magnetic fixation products in the market is uneven, and there is no quality standard for magnetic fixation products used in PC components in the industry. In this case, how can we buy products with reliable quality? To this end, we have compiled a purchase guide for your reference.

1、Brand

In recent years, the supply chain of various supporting equipment, molds and auxiliary materials in the prefabrication construction industry has developed rapidly, but all fields are facing the vicious competition of inconsistent product standards with low price, low quality; How to choose a high-quality product supplier in this chaotic market is the concern of every PC component manufacturer.

In the absence of any product trial comparison, choosing suppliers with brand influence will undoubtedly become a top choice.

And in many brand suppliers, how to choose? This requires comprehensive consideration of the plant equipment, production capacity, qualification certificate, quality control and R & D team of each brand supplier in combination with the enterprise's own development plan.

2、Quality

1).magnetic core

The magnetic core is the core of the whole magnetic fixed product, and the core of the magnetic core is the magnet.

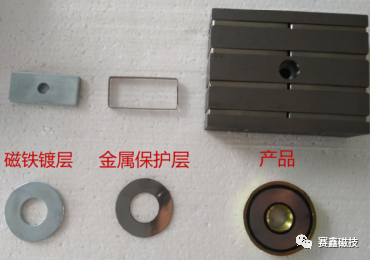

The quality of the magnet will affect the suction of the magnetic core, the coating (anti-corrosion) and metal protective layer (anti scratch) of the magnet will affect the service life of the magnet. Both are indispensable

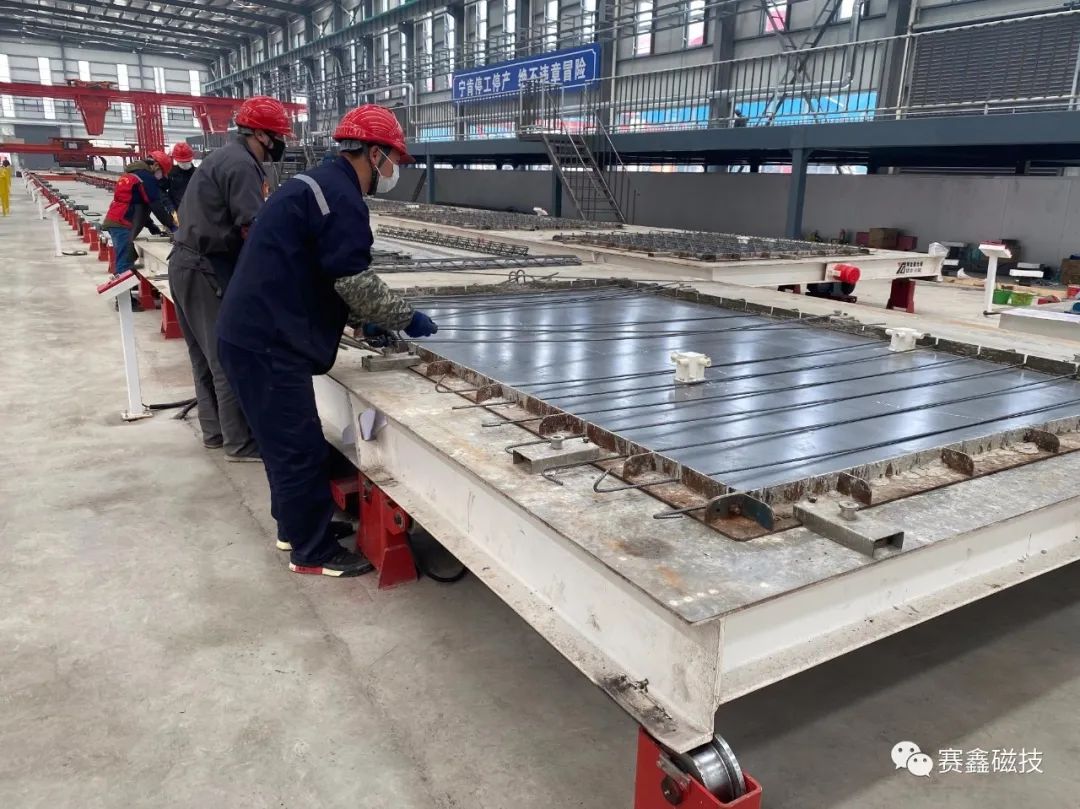

Since the quality of the magnetic core directly affects the working suction of the magnetic box, how to detect the actual working suction of the magnetic box? This requires professional testing equipment, as shown in the figure. Figure 1 shows the suction testing equipment before the magnetic box leaves the factory, and Figure 2 shows the simple testing equipment, which can test the working suction of the magnetic box after use anytime and anywhere, so as to know whether the magnetic box used has demagnetization phenomenon and demagnetization degree.

2). Shell

At present, the shell materials of magnetic fixed products on the market are mostly use high-strength carbon steel and stainless steel, the thickness of shuttering magnet plate is generally 3-4mm.

In terms of strength, high-strength carbon steel is better than stainless steel, and in terms of anti rust performance, stainless steel is better than high-strength carbon steel. When purchasing, you can choose the appropriate material and thickness in combination with the actual use.

In addition, attention should also be paid to the frame structure of the shell. The structure with reinforcing plate and bolt design is stronger and more durable than direct welding.

3). Accessory

Saixin entered many component factories and saw many magnetic boxes. Various quality problems occurred because the quality of selected accessories did not meet the standard.

The auxiliary accessories of magnetic fixed products include switch indenter, spring, bolt, stainless steel ring, etc. when purchasing, special attention should be paid to the quality of accessories, such as the dimensional accuracy of switch indenter, the performance grade of bolt and whether the spring meets the national standard.

The production of magnetic fixed products must have standardized quality inspection procedures from raw material procurement to processing and assembly. Taking the magnetic box as an example, the quality inspection procedures are as follows:

IQC---Semi-finished products inspection ---Finished product inspection ----incoming test---OQC

A small magnet box , from raw materials to finished products must pass all test , can be judged as qualified products . If the magnet box is compared to a car , the magnetic core is the engine , the core of the whole product ; The switch pressure head is the steering wheel, which controls the working direction of the whole product ; the shell and screws are the frame part .A complete magnetic box is the same as a car. The quality of all accessories can not be ignored. If there is a problem with one accessory, the working performance of the whole product will be affected. Therefore, when purchasing, we should choose the products with qualified quality inspection of the brand, rather than blindly pursuing the price and choosing inferior products.

3、model and quantity

After selecting the supplier of magnetic fixed products, how to choose the appropriate magnetic fixed products? This requires comprehensive consideration of the production process of precast concrete products, such as usage scenario of magnetic fixed products (fixed formwork and vibrating formwork), reinforcement spacing, steam curing kiln temperature, mold height, embedded parts specifications and models, etc.

Take the magnetic box as an example. When the laminated plate is produced on the fixed die table, the suction of the magnetic box is recommended to be 600-800kg magnetic box. The service spacing of the magnetic box (generally 1-2m) is adjusted according to the height and thickness of the die.

In the production of assembly line vibration die, 1000 kg magnetic box can better meet the production demand; When producing wallboard, 1350kg magnetic box can be selected; When producing prefabricated beams, columns or other special-shaped components, 1800-2100kg magnetic boxes can be selected to be used together with corresponding fixtures.

With these basic data, we can analyze the total amount and budget of magnetic boxes required by a project

4、Service

Products and services are the embodiment of the company's core values.

From January 1, 2022, Saixin will provide customers who have purchased 1000 magnetic boxes with the magnetic box cleaning machine developed by Saixin to make the magnetic box more effective and prolong the service life.

Saixin Magnetic Technology Co., Ltd. not only provides free technical guidance and product use training before sales, but also promises to provide free maintenance and parts replacement services within one year on the premise of meeting the operation specifications of magnetic products. For magnetic boxes that exceed the service life, paid maintenance services should be provided.

At the same time, Saixin has also formulated the internal quality control system of the enterprise and actively advocated industry standard services, aiming to provide comprehensive magnetic fixation solutions for the production of concrete components , let customers feel relieved to use Saixin ® Brand magnetic fixed products.

Post time: May-12-2022