With the rapid development of building industrialization, magnetic fixed devices in the PC component production process has been gradually widely recognized and applied .

Ningbo Saixin Magnetic Technology Co. , Ltd. is one of the companies focusing on providing a comprehensive magnetic fixed solutions for precast concrete formwork .

One of the first participants and witnesses for the development of the Prefabricated building Industry

Ningbo Haishu Sailuxun Magnet Co. , Ltd. is the predecessor of Ningbo Saixin Magnetic Technology Co. , Ltd. . In 2009, Haishu Sailuxun company was officially registered, the main business is the export trade of magnets and magnetic assembly . After 2010, China’s prefabricated building got a new opportunity, with Shanghai, Beijing, Shenzhen and Shenyang putting forward policy documents to speed up the industrialization of housing. The history of Ningbo Saixin Magnetic Technology Co. , Ltd. is also a shadow of China’s prefabricated building development process. At this time Haishu Sailuxun company received a lot of foreign customers’ orders, at the same moment, Kraft Xie start to research and develop the prefabricated building industry .

In 2012 , Kraft Xie took part in study tour to Europe organized by the Chinese concrete and cement products association CCPA , visiting equipment manufacturers in Germany as well as some precast component factories in Europe. At the end of 2013, he had the good fortune to visit the prefabricated building project in Shenyang with many domestic experts , and at the same time , got to know some of Heilongjiang Yuhui’s first domestic prefabricated building companies. Maybe before he is not sure about the future of the prefabricated building in China , but according to many times inspections and the support policy , Kraft firmly believe prefabricated building industry will flourish.

In order to meet the large-scale demand for magnetic fixers used in the production of PC components in the domestic market, Kraft Xie registered Ningbo Saixin Magnetic Technology Co. , Ltd. in 2014, embedded fixed magnetic base and a series of precast concrete components need to use in the production of magnetic fixer. In 2018, the company moved into the new standardized plant, and invested more than one million to buy high-precision production equipment, while expanding the team, improve the company management system.

SAIXIN’s Popular Product

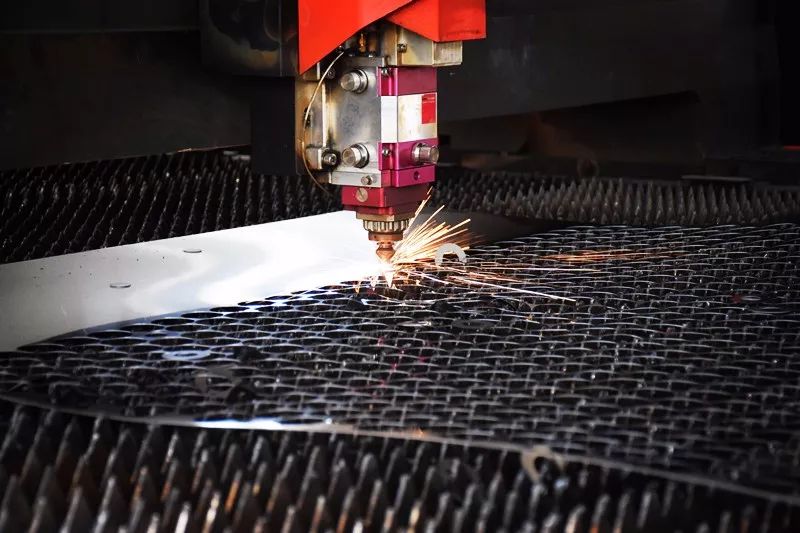

Shuttering Magnet is a magnetic fixing device specially developed for fixing precast concrete formwork . In the production of PC components, compared with the traditional mechanical fixing way such as screw and nut, the magnetic box fixing does not need to be perforated, welded, and will not damage the die platform. Because of its strong holding force, it can effectively reduce the process and time of installing the template, improve work efficiency.

When selecting the magnetic box, the factory should pay attention to the use of the magnetic box, such as the distance between steel bars and the working temperature, etc. , and to combine the fixed mold height (component thickness) to choose the right suction and size of the magnetic box.

For example, in the production of laminated plates on the fixed mould table, the magnetic box suction chosen can be 600-1000kg, while in the production of laminated plates on the vibration mould table, the magnetic box of 1000kg suction is required. In the production of Wallboard, it is necessary to choose 1350 kg or 1800 kg suction magnetic box.

In the process of operation, it is necessary to prevent the magnetic box from deforming due to the impact of hard tools. The bottom of the magnetic box holding surface and the platform should be kept clean and flat, to prevent iron chips or concrete slurry into the magnetic box inside, which will affect the flexibility of the switch, and may cause the magnetic block tilt, can not be flat to fit the platform, reduce the working suction

The Feature of Saixin Shuttering Magnet

Firstly , from the choice of materials whether from the screw strength (Saixin magnetic box screws are 12.9) or magnet quality (magnets from the regular large manufacturers, there are mature testing methods and quality control system) to do the best;

Secondly , the company has a full set of high-precision processing equipment and quality control system, to ensure product quality consistency and stability;

Finally, the company has a professional and experienced technical team, continuous innovation, continuous improvement process, to ensure that products are at a high levelin the industry .

In addition to the shuttering magnet , the magnetic fixed device developed by Saixin for fixing all kinds of embedded parts, as well as the magnetic dripping strip and the magnetic chamfering strip can all play an important role in the production of prefabricated parts.

With the standardization of precast components and the development of intelligent production, shuttering formwork will be more and more widely used in China. Because Saixin’s shuttereing formwork has been widely used abroad, Kraft Xie said, “We have accumulated rich experience on how to apply shuttering formwork to automatic equipment and how to ensure the precision of shuttering formwork in production.”. Our sophisticated production equipment and skilled workers also ensure that we can mass-produce magnetic formwork with high precision and strength.”

Comparison at home and abroad for development of Prefabricated building

Firstly ,Sai Xin ship shuttering magnet ,embedded magnetic base and shuttering formwork to Middle East, Australia, Southeast Asia and other countries . Prefabricated building has been used in many countries abroad. For Foreign Customers, the magnetic box is a special tool for the component factory. Its suction and size are standardized and serialized, customers will according to different sizes and structure of the shuttering formwork, with different fixture use, try to make standardized magnetic boxes can be used for a variety of components and different projects. Therefore, customers are more concerned about the quality of magnetic box, service life and other product performance, and magnetic box shell material is generally high-strength carbon steel, its strength than the domestic prevailing stainless steel magnetic box shell to be strong. In the magnetic box technology, in order to extend the service life of the product, more emphasis is placed on the protection of the rare earth magnets used to prevent the magnets from being corroded and broken in use, thus causing magnetic force attenuation.

As labor costs rise and environmental pressures Mount, prefabricated building is sure to have a bright future in the country. However, due to the fact that it is still in the early stage of development, the specifications of the prefabricated building are not yet perfect, and the design and production of components are not yet fully standardized and automated, thus resulting in the cost advantages and efficiency advantages of prefabricated building scale, the quality advantage did not play out. Although in recent years, a variety of supporting equipment, mold, auxiliary materials and other supply chain development quickly, but each supplier is now facing product standards are not uniform, low-cost and low-quality vicious competition situation.

In this situation, Kraft Xie believes that Saixin still needs to strengthen its own capacity building, build its own brand advantages, speed up the development of new products and improve its service level, and strive to establish long-term cooperative relations with more high-quality customers with good credit. On the other hand, Saixin should expand the international market, strengthen the technology and equipment input on the magnetic edge mould, build up its own competitive advantage, and strive to double the output value again in two years.

Post time: Mar-01-2022