OEM Supply Steel Clamping Magnet - Shuttering Magnet, 1000 KG Precast Concrete Formwork Magnet for Vibration Platform – Saixin

OEM Supply Steel Clamping Magnet - Shuttering Magnet, 1000 KG Precast Concrete Formwork Magnet for Vibration Platform – Saixin Detail:

Product Description

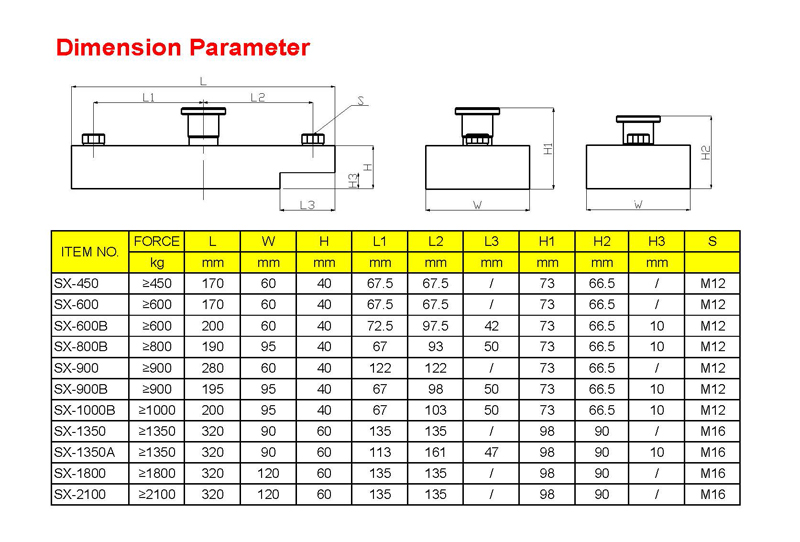

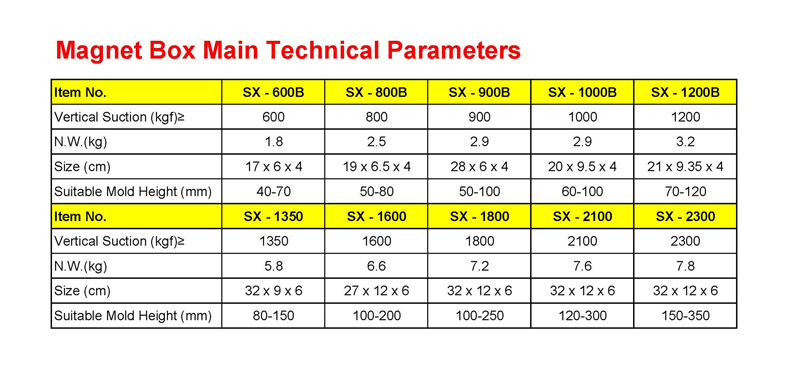

SAIXIN brand SX-1000B magnet box has 1000KGS above adhesive force,you can use the screws to fix the adapter and then we can put it onto the side form.

According to the domestic some side formwork rebar stick out, it require the magnet box size can’t be too wide, our company carefully designed a SX – 1000B side formwork fixed magnet box, the magnet box external dimension is 20X9.5X4CM,suction can reach more than 1000 kilograms.Considering domestic construction site environment is bad at the same time, the concrete grout easy corrosion the magnet box,then effect the switch flexible degree, we use new stainless iron material, not only solves the problems of corrosion protection, also ensures that the magnetic closure effect,at the same time to ensure use safely.

As for the magnet box is used for precast concrete production line, it requires the box surface has high grade rust resistant capability, so that we are using the stainless steel for the cover box.Meanwhile, the inside parts of the cover box are iron material, it still attract magnet block back when we pull the button up.

The adhesive force 1000KGS is enough to fix most sideform, from 60mm to 200mmm height,even on vibration platform. Also the size 200X95X40mm will not occupy much room on the platform.

Instruction

There is an ON/OFF button on the top of the shuttering magnets. At work state, press the button, magnet box fixed the shuttering on the platform firmly, Pull up the button with lever, magnet box is at closed state and can be moved.

(1) The suction of magnet box is based on thickness and smooth degree of the platform, the thicker and smoother the better. And lateral shear force depends on the suction of magnet box and the friction coefficient of the touching surface.

(2)Two screws on two sides of the magnet box can be connected with different adapter, fix different formworks, such as steel angle, steel channel, etc.

(3)SAIXIN® magnet box is made of permanent neodymium magnets, In theory, if the MAX working temperature is below 80℃ and the magnet is not damaged or corroded, the suction will be lasted forever.

Maintenance And Safety Guidelines

(1)In order to avoid the magnet box damaging, do not crash and use hard tools to knock it. Please knock with rubber hammer if must use tools.

(2) Magnet box touching surface should be kept clean and smooth, avoid the scrap iron or concrete grout going inside the box, otherwise the button flexible degree will be affected and the magnet will be slanted, caused the magnet can not be fixed on the platform closely and the suction weakened.

(3)As suction of magnet box is very strong, please avoid closing it to precision instruments,electronic instruments and other iron material. Once they absorb together, it is difficult to separate. Suggest making special tool box to keep them.

(4)Magnet box touching surface should be kept clean and smooth always. And it should be oiled when storage. Max working and storage temperature should be below 80℃,and no corrosive medium around. Always check if the working surface fix the platform closely and the button flexible degree to ensure the normal use.

(5)After using , clean the magnet boxes, and put on stainless steel tool holder. Do not use iron tool holder.

Product detail pictures:

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for OEM Supply Steel Clamping Magnet - Shuttering Magnet, 1000 KG Precast Concrete Formwork Magnet for Vibration Platform – Saixin , The product will supply to all over the world, such as: UAE , panama , Nigeria , The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.