Products

-

-

-

1000kg shuttering magnet

shuttering magnet , suction is 1000kg

-

-

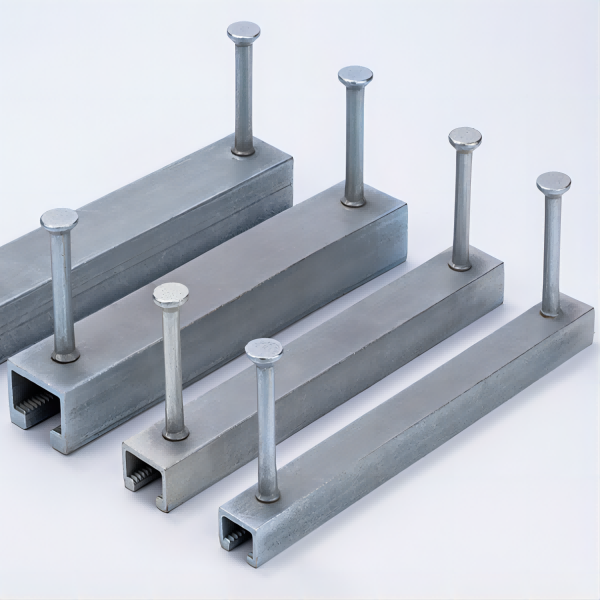

Small Magnetic Test Instrument

As an important auxiliary part of PC production, with the increase of component demand, there are more and more magnet box manufacturers, but there is no unified product quality standard at present. So, in the face of a variety of magnetic boxes, how should customers choose a good magnetic box?

Except material, bending angle, surface treatment, etc., the most important and basic of a high-quality magnetic box is to ensure that the suction meets the product requirements.

In order to let customers clearly “see” the adsorption force of the magnetic box and use it safely, our technicians have specially developed a small magnetic test instrument, which can “portable, easy to use and accurate data”, so that customers can have professional data reference in the process of purchasing the magnetic box and test the suction force of the magnetic box after long-term use, also can evaluate the demagnetization of the magnetic box.

Bad quality and insufficient suction of the magnetic box may lead to mold running and slurry leakage in the production process, and also determine the service life of the magnetic box. Saixin is willing to take the company’s concept of “customer first, pursuit of excellence” as the first element to produce the prefabricated components.

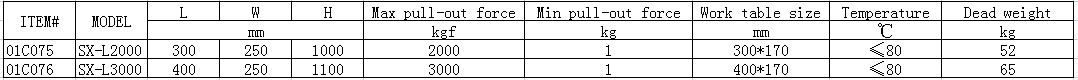

【Product specification】

【 Use-method】

1. Connect the oil pump with the equipment and the sensor with the display. Pay attention to the opening and missing error proofing device at the port.

2. Loosen or remove the screw at the tail of the oil pump (exhaust air), and open the upper cover of the oil cylinder.

3. Rotate the pressure relief screw in front of the oil pump counterclockwise, and then manually press the oil cylinder downward, and the lifting ring can move downward.

4. Place the magnetic box in the center of the workbench (you can use the lifting ring hanging method), and then tighten the screws of the open lifting ring.

5. After manually pressing the oil pump to suspend the magnetic box, operate step 3 again, take out the buckle (do not touch the magnetic box), and press down the magnetic box switch.

6. Adjust the display unit to kg, press the peak value to peak and auto, tighten the pressure relief screw clockwise and start pressing the oil pump.

7. Operate slowly and uniformly during pressing, watch the displayed value, and reduce the operation speed by half when it reaches 80%.

8. When the peak value is reached, the display will display the maximum pull-out value and retain the test data.

【 points for attention】

1. There is a precision sensor on the lifting ring. Please do not collide or be damaged by other external forces.

2. Ensure that the workbench is clean and tidy and oiled to prevent rust.

3. When the oil pump is disassembled, the pressure shall be relieved before operation to prevent hydraulic oil overflow.

4. This equipment is a precision testing equipment, so it should be well protected during logistics and storage.

-

Shuttering Magnet, 1000 KG Magnet For Precast Solid Wall

Product Description Vertical suction: ≥800kgs Size: 19 x 9.5 x 4 cm N.W.: 2.6kgs Be suitable for fixing mold of sandwich panel, inner and outer wall panel suitable mold height recommended: 50-80mm Instruction There is an ON/OFF button on the top of the shuttering magnets. At work state, press the b

-

Cleaning Machine

Magnetic box cleaning machine is specialized in the rapid cleaning of magnetic box machine, it is very convenient to clean the magnetic box, and adapt to different sizes and model. We use high power motors and high quality accessories. So even if the magnetic box that used for a long time, can be made the surface smooth, and use it immediately. The magnetic box cleaning machine used the good quality motor, it is about 1.5KW, and this machine can be matched different kinds of shuttering magnet... -

Lifting Anchor

SAIXIN produced lifting anchor by high grade steel / stainless steel to swift lift precast concrete. The lifting anchor is a traditional lifting anchor system for the precast concrete. The easy and quickly universal head link is used to lift and transport the concrete panel or concrete culvert. the length is made according to client’s request and suitable different strength and weight. There have 4 times safety factor to design these products when we do the test. We only use qualified metal m... -

Magnetic Shuttering System Customization, Precast Concrete Formwork, Suitable For Wall Panel With Rebar Out Of Mold

Shuttering base with different profiles can be specifically made for customer requirements, for example slab supports, wall corner joints and many more. We develop SXB-1802 system exactly according to your needs and requirements. Please do not hesitate to contact us. we can provide the more strong steel shell, and new technology in products, so do not worry, we can meet all your demand. As the factory , the most important things is make sure the products are shipped on time. So do not worry,... -

Shuttering System, Customized Precast Concrete Form For Special Composite Slabs

SXB-1902 is self-designed formwork system. It is easy positioning by fixing and loosening via SX-1350 magnet. It can be handled manually. It is very easy for you to finish precast concrete products quickly, and ensure your project complete on time. Even if you don’t know the product, just tell us what you think and we’ll give you a complete plan. Because the magnet system is located inside the steel shell, the concrete residue or other dirt will not damage the entire formwork sys... -

Magnetic Shuttering System Precast Concrete Formwork For Floor Panel

We offers a well-proven formwork systems that you can choose suit you or have us make one especially for your purposes. SX-7060 is a shuttering system for systematic production of cladding, sandwich walls, solid walls and slabs. The SXB-7060 is available in length up to 3980 mm and heights from 60 mm up to 400 mm, with or without chamfer. The system can be used for manual and robot handling. Economical aspect is: to use less plywood, to reduce moulding and demoulding time, easy cleaning and a... -

Shuttering Magnet, 900 KG Precast Concrete Magnets for Sandwich Panel Wall Panel Formwork System

Product Description This is our new design shuttering magnets,the holding force is 900kgs. SAIXIN magnet box is the new magnetic fixture designed for fixing precast concrete formwork, compared to the traditional way of bolted fixing, magnet box can be disassembled quickly with flexible operation, strong holding force, and consequently improve the work efficiency, reduce man power, low down the wastage of the steel platform, now the magnet box is used worldly in PC industry. As for the magne...